Doritos snack food chips production line

Doritos Corn Chips Fryer Making Machine

Doritos corn chips fryer making machine introduction:

This production line can make different kinds fried snacks(such as rice crusts,chips bugles,pizza rolls,doritos)based on changing die moulds and manufacturing technique.The production process includes mixing,extruding,cutting,frying,flavoring and packing.The products are crispy and less oil.

*Machines matrials:All the machines are made by 304 stainless.

*Products:By changing the mould of machine we can produce rice crust,French fries,bugles,fish cake,pizza rolls,crisp fruit,triangles,and other product.

*Voltage in china:Three phases:380V/50Hz,Single phase:220V/50Hz,we can make it according to customers' Local voltage of different countries.

Samples for reference:

Doritos corn chips fryer making machine flow:

| NO | Machine | Apllication/Use |

| 1 | Mixer |

Mixed raw materials |

| 2 | Screw-conveyor |

Send the raw material to the extruder |

| 3 | Twin-screw extruder |

Extruded the material by the twin screw |

| 4 |

Cutter-QY |

Cutter the chips or sticks products |

| 4' |

Shaping cutter |

Cutter the bugles,doritos or 3D snacks |

| 5 |

Continuous fryer |

Frying the product,making it more crispy |

| 6 |

Deoiling machine |

Deoiling the product |

| 7 |

Flavoring line |

Flavoring the product |

Doritos corn chips fryer making machine technical parameters:

| Modle | TSE65 | TSE70 |

| Installed power | 88kw | 126kw |

| Power consumption | 65kw | 82kw |

| Production capacity | 100-150kg/h | 200-260kg/h |

| Dimension(L*W*H) | 15*2*3m | 22*2*3m |

Doritos corn chips fryer making machine features:

1.Low power consumption.

2.Long life and cheap spare parts.

3.By changing the mould of the machine,you can produce ball,stick,ring,star,wheel,flower and heart-shaped products.

4.The whole production line is easy to operate,only need two or three workers to control the production line.

Doritos corn chips fryer making machine configuration:

Mixing system---Extrusion system----Cutting system---Fried system----Flavoring system--Packing system

Detailed structure of twin-screw extruder:

The Twin-screw extruder is made up of the feeding system ,extruding system,cutting system,heating system,transmission system and controlling system.We will feed the material from the feeding machine and get the tissue state by inflating the material and the machine barrel must be high temperature,high pressure and high cutting.The material can be sterilized by the high temperature and high pressure.

Another configuration:

Different cutting machine:

Different fryer:

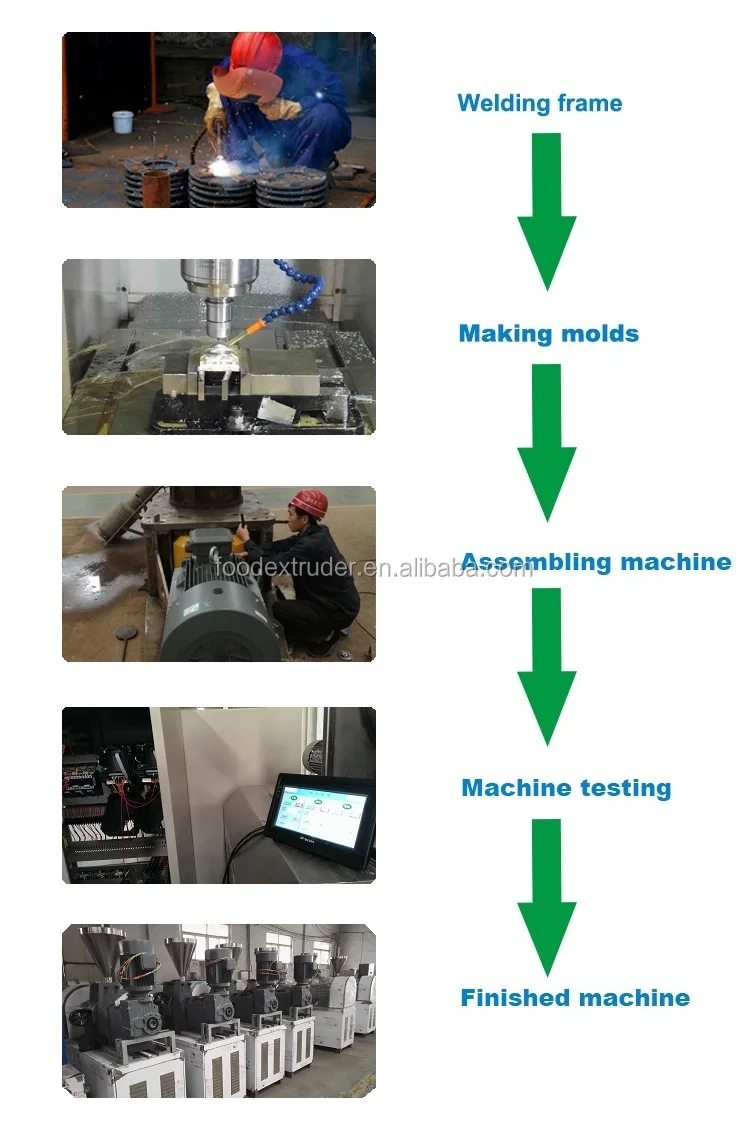

Doritos corn chips fryer making machine flow chart:

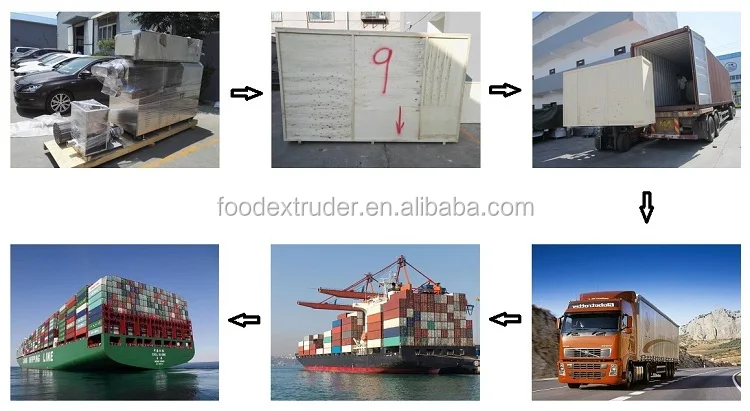

1. Packing machines into wooden cases;

2. Let trucks take containers to our factory for safely loading;

3. Sending to port for boarding and transportation.

4. We also can send machines by air and train.

Pre-sale services:

1.Provide 24 hours online service;

2.Provide the standard device and the flow chart;

3. According the clients’ special requirement,offering the reasonable plan and free design helping to select the equipment;

Services during the sales:

1.Provide the basic formula;

2.Inspect the machine before leaving the factory;

3.Oversea installation and commissioning the equipment;

4.Free management of equipments’ long distance shipping;

After sale services:

1.Provide 1 year complete warrantee and life-time maintenance service;

2.Overseas installation and train the first-line operators;

3.Provide the spare parts will at preferential price for an extended long time;

Certification:

Jinan Shengrun Machinery Co.,Ltd is an industry and trade integrated enterprice. The company is committed to research and develop extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system,baby food system,corn puff snacks system, pellets system, artificial rice system, soynuggets system; as well as pet food/fish food system.

Our factory was founded in 2009. As the owning import and export right, machines are exported to more anda more countries directly by ourselves. For supplying best servies, technology department, sales department, producing department, after sales services department are always available for you.

Our machines have been exported to many countries of Asia, America, Africa etc. Machines are popular in the countries. So until now, there are not only direct customers, but also some long term cooperation agents.

Don't hesitate to contact us. Our team from pre-sale service to after-sale service will prove that your choice is worth it.

Q1.Are you a manufacturer or a trading company?

A:We are a professional manufacturer of food&feed machine.

We have own factory and R&D department.

Q2.Can you provide food or feed formula?

A:We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q3.What after-services do you provide?

A:Send engineers for installation,trial running and trianing workers at customer’s site.

Handling the problems occurred during use.Supply spare and wearing parts on discount.

Help customers to solve any other problems.

Q4. What is your payment terms?

A: Strongly recommend to use Alibaba’s Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available.

Other payment is negotiable.

Related Article

New fried snack testing by our food equipment

- Previous:None

- Next:Puffed rice crust production line

- Pet Food(dog food) Machinery

- Pet Chews production line

- Breakfast Cereals Corn flakes Machinery

- Bugles/Doritos/Tortilla processing line

- Kurkure/Cheetos/Nik Naks Machinery

- Pasta/Macaroni Machinery

- Textured Soy Protein Machine

- Nutritional Rice Machinery

- Nutritional Powder/Baby food Machinery

- Bread Crumbs Machinery

- Instant Noodles Production line

- Modified Starch Machine

- Packing Machine

- Extruder

- Drying & sterilization machines

- Matched machineries&Extruder accessories

- Edible rice drinking straw prodution line

- Eco friendly products production line